Palisade Fences, Galvanized, Powder Coated, Black Finishes

- Hot Dipped Galvanised Palisade Fencing

- Prefabricated Steel Palisade Fencing Painted

- Black Coated Steel Palisade Fencing

- Powder Coated Galv. Steel Palisade Fence

- Wrought Iron Palisade Fence

- GRP Palisade Fencing

Steel Palisade Pale Types

Fencing Heads Shapes

- Palisade Fencing Tops General Intro

- Palisade Fence with Round and Notched Top

- Triple Spike Pointed Palisade Fence

- Single Pointed Palisade Fence

High Security Fence Systems

- Perimeter Safety Palisade Fence System

- Palisade Fence Hot Rolled Galvanized

- Substation Security Paliasade Fence

- Razor Wire Topped Palisade Fencing

- High Security Palisade Fencing

- Palisade Curved Fence Panels

- Razor Barbed Wire

- Concertina Razor Barbed Wire

- Single Spiral Razor Wire

- Y Steel Palisade Fence with Concertina Razor Wire

- Chain Link Security Fencing

- Fencing Razor Spikes

- Weldmesh Panels

- Curved Welded Wire Mesh Fence

- Fencing Gates

STRANDED BARBED WIRE, RAZOR BARB WIRE AND CONCERTINA

Security barbed wire is supplied in three forms: Twisted barb wire, razor barbed wire and concertina barbed wire.

Barbed wire and spikes are all mounted along top rails of fencing panels for high level of security purposes.

Stranded Barbed Wire

Materials:

Electro-galvanized

Hot dipped galvanized

Plastic coated galvanised steel

Main types:

Single barbed wire or single strand barbed wire

Hot Dip galvanized steel barbed wire, HDG Galv.

Reverse twisted galvanized barbed wire

Double strand barbed wire, electro-galvanised and zinc galv.

Typical size:

Wire gauge: BWG14

Barb distance:12.5 cm

Barb length: 1.8 cm

Finish: HDG hot zinc plate (zn)

Strand: Double

Razor Barbed Tape Wire ( Simplified as RAZOR WIRE)

Materials:

Hot dipped galvanized steel

Stainless steel 304, 316.

Forms:

Razor barb wire coils

Razor wire flat wrap

Razor wire can also be made welded mesh sheet ( in square and diamond hole).

Concertina Barbed Wire ( Simplified as CONCERTINA COILS)

Concertina wire is spiral type high-security barbed wire designed for physical perimeter and security fencing in military and border security.

Materials:

Heavy galvanized (HDG Galvanised)

SUS304

SUS316

Supplied with concertina barbed wire, post, support poles

Standard: BS 1706, ISO 550, BS.EN.10002 and BS 443: 1982.

Blade types: CBT-65, BTO-22, etc.

Specifications of Concertina Razor Wire Coils Applied for High Security and Military Uses

| Coil Diameter | 450 mm (18 inch) | 730 mm HS (28 inch) |

730 mm HD (28 inch) |

980 mm HS (36 inch) |

980 mm HD (36 inch) |

1250 mm (50 inch) |

|---|---|---|---|---|---|---|

| Recom-mended Stretch Length |

10 m (32 ft.) |

10-12 m (32-38 ft.) | 15-20 m (50-76ft.) |

10-15 m (32-50 ft.) |

8 m (26 ft.) |

10 m (32 ft.) |

| Coil Diameter When Stretched |

400 mm (16 in) |

620 mm (24 inch) |

600 mm (24 inch) |

820 mm (32 inch) |

850 mm (33 inch) |

1150 mm (46 inch) |

| Spiral Turns Per Coil |

54 / 55 | 54 / 55 | 54 / 55 | 54 / 55 | 54 / 55 | 54 / 55 |

| Clips Per Spiral | 3 | 5 | 3 | 5 | 7 | 9 |

| Quantity Per 6m/20ft Shipping Container |

3200 | 1500 | 1500 | 1240 | 1200 | 450 |

| Note: HS = High Strength; HD = High Density | ||||||

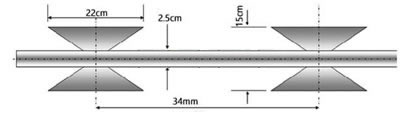

Concertina Wire with blade type BTO22

Barbed wire, blade type BTO22, in crossed coils, fixed with clips

Diagram:

Construction:

Barbed wire consists of wire enclosed with metal band – blades and tied with staples;

The barbed wire is wrapped in rolls and is expandable from them.

Wire:

Diameter: 2,5 mm (±0,2 mm);

Zinc-plate metal, according to BS 1706 standards, minimum galvanizing 100g/m2 (±20 g);

Minimum elasticity of metal wire according to1400 MPA.

Blades:

Thickness 0,5 mm (±0,2 mm);

Blade type BTO22;

Zinc coating according to ISO 550 standard, minimum galvanizing 200 gr / m2;

Cutting (tear off) force of blades from wire — not less than 450 N;

Symmetrical blades on both sides, with a total width 15 mm (±2 mm);

Blade length – 22 mm (±2 mm);

Distance between blade centers35 mm (±2 mm).

Staple:

Number of staples – 3 (for the diameter of the outer roll 400-600 mm);

Number of staples – 4 (for the diameter of the outer roll 700-800 mm);

Number of staples – 5 (for the diameter of the outer roll 900-1000 mm);

Zinc-plate metal, according BS1706 standard, minimum galvanizing 200g/m2 (±20 g);

Thickness of metal 1,5 mm (±0,2 mm);

The clamping force of the wire shall not be less than 1500 N without causing a staple deformation.

Notes:

No diameter changes are allowed when the wire is rolled-out (expanded) >5%;

Minimum length of roll in expanded form – 10 m;

Number of turns in a roll — not less than 54.

400 mm-600 mm;

700 mm-800 mm;

900 mm-1000 mm.

Quality Standard:

Each batch produced must be accompanied by a manufacturer's declaration of conformity.

Barbed wire as a product must meet at least the following standards based on EU accredited and verified laboratory test results :

BS1706 – zinc and cadmium application technology on metal;

BS.EN.10002 – metal tensile flexibility test ;

BS 443:1982 – zinc coating test on metal.

Colour: Galvanized metal colour

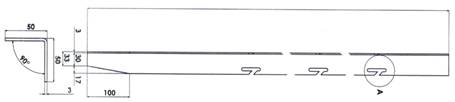

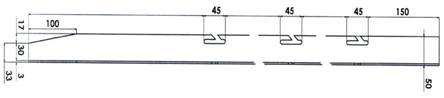

Poles 0,8m/ 1,6m/ 2m for Fixing Concertina Wire to Fence

Material: Hot zinc-plate iron

Tapered tip of peg:symmetrically tapered at 45 degrees (± 2 degrees) from both sides. Length of pointed end 100 mm (±2 mm)

Form: L-shaped with edge width 35x35 - 50x50 mm (±2 mm)

Material thickness: 5 mm (±1 mm).

Number of pole sections for fixing the fence from above on both sides of the L-shape::

1. For poles with length 0,8 m (±10mm) – not less than 2 sections;

2. For poles with length 1,6 m (± 20mm) – not less than 4 sections;

3. For poles with length 2 m (± 20mm) – not less than 6 sections.

Spacing from top of peg to first incision 150 mm (±10mm).

Spacing between sections 200 mm (±10 mm).

The shape of the section according to the imagee or equivalent .

Depth of section 17 mm (±2mm).

The widest part of the section 45 mm (±2mm).

Metal hardness:at least 90HRB according to Rockwell's hardness test (US) or equivalent.

Weight:

For poles with length 0.8 m – not more than 3.10 kg.;

For poles with length 1.6 m – not more than 6.10 kg.

For poles with length 2 m. – not more than 7.6 kg.

Processing:hot zinc treated (Zn)

Corrosion protection: zinc (Zn) coating at least 100 µm (micron)

Palisade Fences Finishes

High Security Palisade Fence Systems

- Palisade Fencing for High Security Purpose

- Palisade Curved Fence Panels

- Razor Barbed Wire

- Concertina Razor Barbed Wire

- Single Spiral Razor Wire

- Y Steel Palisade Fence with Concertina Razor Wire

- Chain Link Security Fencing

- Razor Spikes

- Weldmesh Panels

- Curved Welded Wire Mesh Fence Panels

- Fencing Gates

31 Xinjie, Development Area, Dezhou, China www.palisadefence.net sales@palisadefence.net

Copyright © 2020. Tripline Palisade Fence Co.